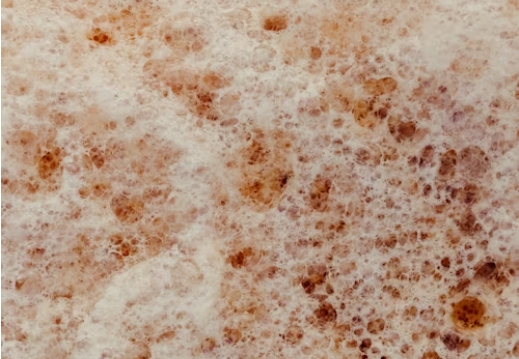

Printing ink defoamer for smoother printing

May 14, 2024

with the progress of digital printing technology, the demand for digital printing ink is also growing, digital printing ink has the advantages of fast colour adjustment, high printing accuracy, adaptability, etc. To meet the demand for personalized printing. But at the same time for the performance of the ink also has high requirements, need to have a certain anti-foaming, so printing ink defoamer application and birth.

Features:

1. High efficiency defoaming: printing ink defoamer can quickly and effectively eliminate air bubbles on the surface of the ink, providing uniform, bubble-free printing effect.

2. Good dispersibility: it can disperse the air bubbles evenly in the ink, avoiding the aggregation and accumulation of air bubbles, ensuring the quality of printed products.

3. Durability: The antifoaming effect provided is durable and can remain effective during the printing process, reducing the re-generation of air bubbles.

4. Adjustability: the defoamer for printing ink has good adjustability, and the dosage and concentration of the defoamer can be adjusted according to the specific needs in order to obtain the appropriate defoaming effect.

5. Compatibility: It can be compatible with different types of printing inks, including water-based ink, solvent-based ink, UV ink, etc., with a wide range of applications.

Application:

1. Graphic printing: defoamer has an important role in the field of graphic printing, which can be used in the printing of paper, cardboard, packaging materials, etc. to provide high-quality printing effect.

2. Flexible Packaging Printing: It can be used in flexible packaging printing, such as food packaging, pharmaceutical packaging, etc., to ensure that the surface of the printed matter is bubble-free and legible.

3. High-precision printing: It has an important position in high-precision printing fields, such as electronic component printing, label printing, etc., to ensure the printing quality of fine patterns.

4. Screen Printing: It is commonly used in screen printing to improve the fineness of the screen and avoid the effect of air bubbles on the printed materials.

According to different formulations and conditions of use, it is necessary to choose the appropriate type and amount of defoamer. Too much or too little defoamer will affect the defoaming effect and product performance, so it is necessary to carry out reasonable mixing and testing.

Click on the related products links:RK-857/RK-801